By: Pacific Corrugated Pipe Company

CSP & Pipe Arch Project of the Year Delivers Under Pressure

The Gilman Springs Road Widening wasn’t just another infrastructure upgrade—it was a nationally recognized success. Completed by Pacific Corrugated Pipe Company, this standout project earned the title of NCSPA CSP & Pipe Arch Project of the Year for its precise execution, life-saving design, and creative use of custom beveled steel drainage pipe.

Located near Hemet, California, Gilman Springs Road had long been known for its high accident rate. What looked like a basic two-lane road actually posed a serious safety hazard for local drivers. To correct that, the plan was simple: widen the road and add a center median to prevent risky passing. Straightforward in theory—but far more complex in practice.

No Bypass, No Margin for Error

In a bold move, officials decided to fully close the road for just 30 days to fast-track construction. That choice came with serious pressure. Contractors had to work around the clock to hit the deadline. And the drainage component? It had to be perfect from day one.

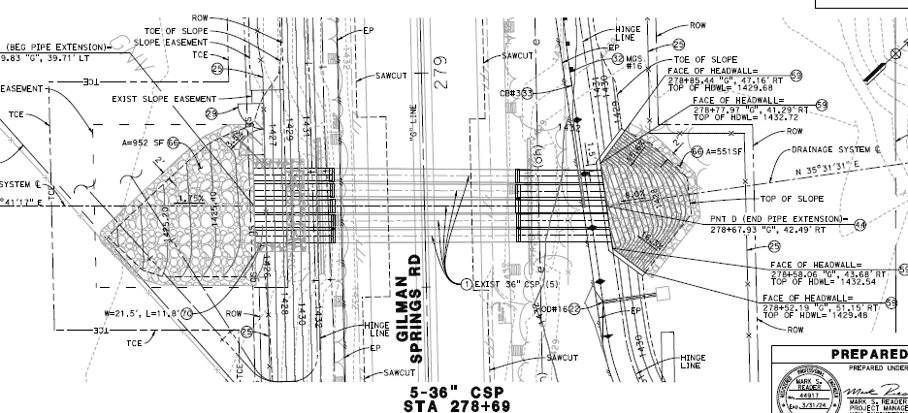

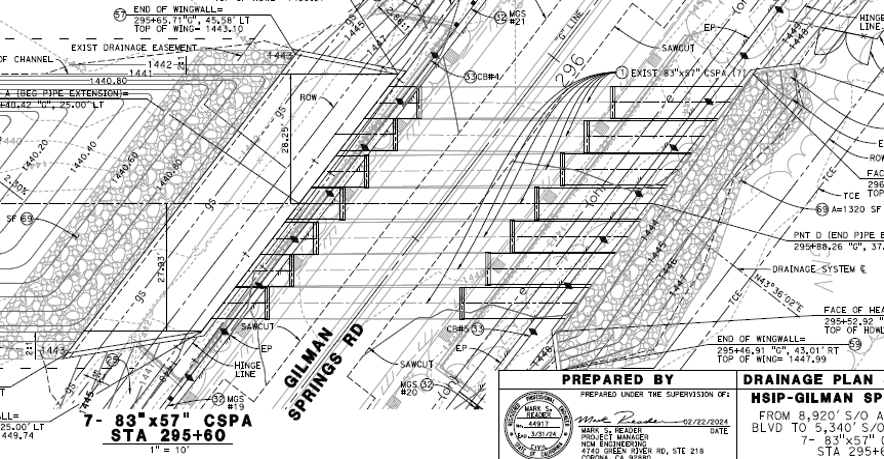

Pacific Corrugated Pipe Company stepped up with exactly the right solution: custom beveled steel drainage pipe designed to meet the tight specs of the project. Over 127 pipe lengths and 57 unique bevel angles were needed—cut into both round and arched profiles, all fabricated from tough 10-gauge steel.

This wasn’t your average pipe order. It was a masterclass in precision-fabricated steel culverts, aligned with federal culvert design standards and built with pinpoint accuracy to match the site’s evolving conditions.

Smart Spreadsheets, Smarter Steel

To manage the project’s complexity, the team created a detailed spreadsheet that identified every single pipe segment across the entire drainage system. Each entry listed the pipe number, length, diameter, profile type, skew angle, and even inlet and outlet configurations. That spreadsheet wasn’t just helpful—it was essential for staying on track.

These details ensured nothing was overlooked during fabrication or delivery of the custom beveled steel drainage pipe. With such an aggressive schedule, even a single error could have caused costly delays. That’s why the predictability and resilience of steel were so important. No other material could’ve delivered the same level of confidence and precision.

CAD Meets Culvert: Visualizing Every Bevel

The precision didn’t stop with spreadsheets. Pacific Corrugated Pipe Company also created CAD drawings for each pipe run, mapping both inside and outside measurements of the bevel cuts. This gave the production team crystal-clear guidance for fabrication and installation, especially when dealing with dozens of unique angles.

These drawings helped bring order to chaos and showcased why custom beveled steel drainage pipe is the go-to choice when accuracy and turnaround time matter most. Plastic or concrete alternatives simply wouldn’t have performed at this level.

Safer Roads, Smarter Design

Gilman Springs Road had long been a high-risk route, with its accident-prone design flagged as a concern for years. The upgrades made here are a textbook example of how smarter infrastructure supports highway safety initiatives aimed at saving lives. What once posed a danger to drivers is now a safer, more reliable roadway thanks to careful engineering and top-tier materials.

This award-winning project shows the strength of collaboration between skilled contractors and expert manufacturers like Pacific Corrugated Pipe Company. When time is tight and the demands are high, steel—and the teams who know how to use it—rise to the occasion.

RELATED STORIES

Project Spotlight: Hardin Valley Middle School Entrance

2023 Project of the Year – DOT Winner: Yellow Mill Bridge CT DOT Rehab

Tennessee’s Award-Winning Infrastructure: Powering Electric Vehicle Production – 2025 NCSPA Connections Project of the Year