By: Contech Engineered Solutions

Top Honors for Rail Trail Culvert Replacement: Hardwick 32A Rebuild Earns NCSPA DOT Project of the Year

The Lamoille Valley Rail Trail (LVRT) in Northern Vermont is a cherished pathway. It fosters recreation and significantly boosts local economies. However, a substantial challenge recently confronted this vital community asset. It demanded an expert rail trail culvert replacement. Fortunately, innovative engineering and dedicated collaboration restored Hardwick Culvert 32A. This remarkable achievement also earned the prestigious NCSPA DOT Project of the Year award.

Snowmobilers, pedestrians, and cyclists enjoy this vital trail year-round. On July 10, 2023, unprecedented rainfall occurred. Between 7.6 and 22.9 centimeters fell in just 48 hours. This triggered widespread catastrophic flooding. Multiple washouts occurred along the trail. Hardwick Culvert 32A was one of the hardest-hit locations. Undersized twin brick culverts from the old rail line became clogged with debris. This blockage created a dam. It exacerbated the significant nearly 18.3-meter elevation difference between the trail and the stream.

The Vermont Agency of Transportation (VTrans) promptly implemented a temporary bypass. This maintained some connectivity. Simultaneously, the primary focus shifted. VTrans aimed to develop a permanent and resilient crossing solution. This crucial rail trail culvert replacement at Hardwick Culvert 32A was essential. This proactive approach demonstrated a commitment to restoring this vital link for the community and trail users.

Overcoming Engineering Hurdles for the Award-Winning Rail Trail Culvert Replacement

The tight construction window in Vermont, coupled with the urgent need to address numerous life safety crossings damaged by the July floods, made engineering and construction in 2023 impractical. This was the case for this complex culvert replacement. Consequently, VHB Engineering took on the critical task of designing a permanent replacement for the washed-out Hardwick Culvert 32A. This project would ultimately earn significant recognition for its innovative approach to rail trail culvert replacement.

The selection of an appropriate structure presented several engineering challenges. The presence of bedrock immediately ruled out a closed bottom design. This would have necessitated extensive blasting and the placement of a substantial amount of lightweight fill to manage the overburden. Furthermore, smaller corrugated structures lacked the necessary end area. Also, they lacked the capacity to support the significant fill above the arch for this vital culvert replacement.

While precast arch options were considered, they posed a risk to the timeline for reopening the trail by the fall of 2024. Similarly, the logistical complexities of installing a single-span truss bridge threatened to push the project schedule into the harsh winter months. Ultimately, a single radius arch with a 18.3-meter span and a 9.1-meter rise, constructed from robust deep corrugation structural plate material, emerged as the ideal solution for the Hardwick Culvert 32A rail trail culvert replacement.

This substantial structure offered sufficient height to minimize cover requirements, ensuring its structural integrity. The underlying bedrock provided excellent bearing capacity, simplifying the foundation design for the large arch. The design and fabrication of the deep corrugated structural plate could be accomplished within an impressive six-month timeframe. This aligned perfectly with the project’s ambitious schedule for the award-winning culvert replacement at Hardwick Culvert 32A.

Efficient Construction and Innovative Technology in the Rail Trail Culvert Replacement Project

With a robust design complete, the state quickly began material procurement. Contractors submitted bids for the Hardwick Culvert 32A installation. This culvert replacement project was destined for award recognition. CCS, a local firm known for bridge and vertical construction, was selected. CCS was well-suited for this culvert replacement. They efficiently managed site excavation and foundation casting. This occurred while the deep corrugation structural plate arch was being fabricated.

Rapid Arch Assembly: A Testament to Expertise in Rail Trail Culvert Replacement

Plate material arrived on-site in early July. In under three weeks, CCS assembled the impressive 44.2-meter long beveled end arch. Their precise fit-up showcased their steel erection expertise. Contech’s exceptional fabrication abilities also contributed to this award-winning rail trail culvert replacement at Hardwick Culvert 32A.

Innovative Technology Enhances Rail Trail Culvert Replacement

VTrans strategically integrated innovative technology into the Hardwick Culvert 32A rail trail culvert replacement. Geogrid attached to the arch’s beveled ends was a key feature. This ingenious addition stabilized the backfilling process. It eliminated the need for traditional external bracing on the stream side. This was crucial for the rail trail culvert replacement.

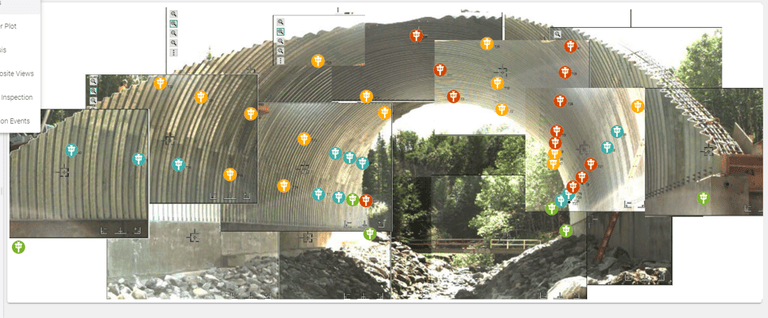

Furthermore, an advanced shape monitoring system tracked the arch’s geometry during backfilling of the Hardwick Culvert 32A rail trail culvert replacement. Prisms were placed inside the arch. A solar-powered device monitored these points. It transmitted any arch movement in real-time. This data went to the owner, contractor, engineer, and Contech. Nearly fifty locations within the arch were monitored. This ensured clear communication about its structural behavior. All stakeholders involved in the award-winning culvert replacement at Hardwick Culvert 32A benefited. This real-time data was invaluable. It led to adjustments in the backfill procedure. Pressure on the arch was minimized while maintaining proper compaction for this vital culvert replacement. After backfilling, a field-cast concrete collar was poured around the beveled ends. This provided extra stability and protection to the award-winning culvert replacement at Hardwick Culvert 32A.

A Lasting Legacy for the Lamoille Valley Rail Trail Thanks to the Award-Winning Rail Trail Culvert Replacement

Ultimately, the successful completion of the new Hardwick Culvert 32A crossing marked a significant triumph in rail trail culvert replacement. Consequently, this achievement allowed the Lamoille Valley Rail Trail to reopen for autumn travelers. Moreover, this remarkable effort earned the prestigious NCSPA DOT Project of the Year award. Indeed, this installation provides a safe and economical solution. Furthermore, it promises to be resilient and virtually maintenance-free. Consequently, it will serve as a valuable asset for generations to come. Therefore, the innovative engineering and construction techniques employed in the Hardwick Culvert 32A rail trail culvert replacement project not only addressed an immediate need but also set a benchmark for future infrastructure endeavors.

Related Stories

Project Spotlight: VT Route 2B Bridge Replacement

Poe Paddy State Park Tunnel – 2016 NCSPA Rehabilitation Project of the Year

2021 Project of the Year Winner – Polymer Coating: Hydrite Chemical Rail Expansion